| Specification |

|

Payment |

Other |

| Packing |

|

Price Terms |

Ex-work Without Tax |

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em; color: rgb(0, 0, 0); font-family: Arial, Helvetica, sans-serif; line-height: 24px;">

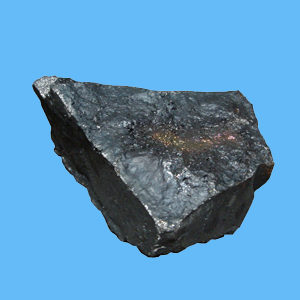

<span style="margin: 0px; padding: 0px; outline: 0px; font-size: 14px; font-family: arial, sans-serif; line-height: 28px;">Cr12模具钢为典型的合金工具钢,是应用广泛的冷作模具钢,具有高强度、较好的淬透性和良好的耐磨性,但冲击韧性差。</span></p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em; color: rgb(0, 0, 0); font-family: Arial, Helvetica, sans-serif; line-height: 24px;">

</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; font-size: 14px; text-indent: 2em; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

是应用广泛的冷作模具钢,具有高强度、较好的淬透性和良好的耐磨性,但冲击韧性差。主要用作承受冲击负荷较小,要求高耐磨的冷冲模及冲头、冷切剪刀、钻套、量规、拉丝模、压印模、搓丝板、拉延模和螺纹滚模等。</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; font-size: 14px; text-indent: 2em; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

Cr12属于高碳高铬莱氏体钢,也是应用广泛的冷作模具钢.该钢具有较好的淬透性、耐磨性、热加工性.碳化物在钢中分布较好,可用于制造形状复杂、工作条件繁重下的各种冷作模具.如冷冲模冲头、螺纹滚模、拉丝模、料模、冶金粉模、木工切削工具、冷切剪刀钻套及量规等工具.我们在研制中,经过反复探索和试验,制订了合理的冶炼工艺和特殊的锭模及锻造工艺,使材质组织达到均匀一致,另外对标准物质加工,大胆创新,采用双刀切屑新工艺,极大提高了功效,缩短了周期,降低了成本。</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; font-size: 14px; text-indent: 2em; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

1.厚度不大于2MM薄板材,高效落料模,冲载模及压印模。</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; font-size: 14px; text-indent: 2em; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

2. 各种剪刀,镶嵌刀片,木工刀片。</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; font-size: 14px; text-indent: 2em; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

3. 螺纹轧制模和耐磨滑块。</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; font-size: 14px; text-indent: 2em; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

4. 冷镦模具,热固树脂成型模。</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; font-size: 14px; text-indent: 2em; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

5.伸拉成型模,冷挤压模具。</p>

<div style="margin: -7px 0px 0px; padding: 0px; outline: 0px; font-size: 14px; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

碳 C :2.00~2.30</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

硅 Si:≤0.40</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

锰 Mn:≤0.40</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

硫 S :≤0.030</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

磷 P :≤0.030</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

铬 Cr:11.50~13.00</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

镍 Ni:允许残余含量≤0.25</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

铜 Cu:允许残余含量≤0.30</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

钴 Co:≤1.00</p>

</div>

<h3 style="margin: 0px; padding: 0px; outline: 0px; font-size: 14px; width: 942px; height: 31px; background-image: url(http://www.zcwz.com/gonghuo/images/bg3.gif); line-height: 31px; color: rgb(57, 57, 57); font-weight: 500; font-family: arial, sans-serif; background-repeat: repeat no-repeat;">

<span style="margin: 0px 0px 0px 10px; padding: 0px; outline: 0px; font-size: 18px; font-family: 'microsoft yahei', Arial, Helvetica, sans-serif;">力学性能:</span>折叠</h3>

<div style="margin: -7px 0px 0px; padding: 0px; outline: 0px; font-size: 14px; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

硬度 :退火,269~217HB,压痕直径3.7~4.1mm;淬火,≥58HRC</p>

</div>

<h3 style="margin: 0px; padding: 0px; outline: 0px; font-size: 14px; width: 942px; height: 31px; background-image: url(http://www.zcwz.com/gonghuo/images/bg3.gif); line-height: 31px; color: rgb(57, 57, 57); font-weight: 500; font-family: arial, sans-serif; background-repeat: repeat no-repeat;">

<span style="margin: 0px 0px 0px 10px; padding: 0px; outline: 0px; font-size: 18px; font-family: 'microsoft yahei', Arial, Helvetica, sans-serif;">热处理规范:</span>折叠</h3>

<div style="margin: -7px 0px 0px; padding: 0px; outline: 0px; font-size: 14px; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

热处理规范:1)淬火,950~1000℃油冷;2)淬火980℃,油冷,180℃回火2h。</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

金相组织:回火马氏体+未溶碳化物+残余奥氏体。</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

● 交货状态:钢材以退火状态交货。</p>

</div>

<h3 style="margin: 0px; padding: 0px; outline: 0px; font-size: 14px; width: 942px; height: 31px; background-image: url(http://www.zcwz.com/gonghuo/images/bg3.gif); line-height: 31px; color: rgb(57, 57, 57); font-weight: 500; font-family: arial, sans-serif; background-repeat: repeat no-repeat;">

<span style="margin: 0px 0px 0px 10px; padding: 0px; outline: 0px; font-size: 18px; font-family: 'microsoft yahei', Arial, Helvetica, sans-serif;">Cr12淬火温度</span>折叠</h3>

<div style="margin: -7px 0px 0px; padding: 0px; outline: 0px; font-size: 14px; color: rgb(0, 0, 0); line-height: 24px; font-family: arial, sans-serif;">

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

Cr12淬火950~1000℃油淬,二次回火550℃</p>

<p style="margin: 0px; padding: 0px 12px; outline: 0px; text-indent: 2em;">

高温淬火1100-1150℃,低温淬火960-1050℃,回火550-650℃,前者有二次硬化现象,回火不少于2次,每次2h,回火后可空冷或油冷,高温淬火前最好进行2次预热,在高温加热时,需采取保护措施,以防氧化。</p>

</div>

<p>

</p>